The Materials Science RPA periodically runs funding competitions across a variety of categories including Seed Grants, Equipment Grants, Vouchers for User Center Access, Conference Grants, Student Support Grants, and Faculty Success. See below for recent awardees listed by category with project abstracts.

FY2024 Awards Funded by mRPA

Seed Grants

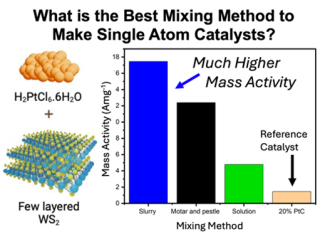

Single Atom Catalysts on Chalcogenide Supports Through Intense Pulsed Light (Aron Huckaba, Chemistry)

Heterogeneous metal catalysts are the most used type of catalyst used industrially. Unfortunately, the metal catalyst particle size distribution and metal catalyst dispersion within the support are difficult to control with current synthesis protocols. One especially important type of reaction is the hydrogen evolution reaction, which will are useful in water electrolyzer devices. To make meaningful improvements to the gold standard material (20% Pt/C), the metal catalyst should be reduced as much as possible while increasing the catalyst loading in the support as much as possible. Accordingly, the ideal catalyst would then be single atom catalysts that could be dispersed inn the support at high catalyst loadings. This project aimed to accomplish both of these goals through the intense pulsed light annealing of Pt (IV) precursors. We studied how varying the mixing method between the Pt precursor, (H)2(PtCl6), and the WS2 support affected the Pt loading and the catalytic performance. Additionally, we synthesized alternative Pt precursors (NH4)2(PtCl6) and (H3CNH3)2(PtCl6). We found that when using the (H)2(PtCl6) precursor, the highest mass activity during the hydrogen evolution reaction was highest for slurry mixed catalysts, followed by dry mortar and pestle mixed, then followed by solution phase mixing. Each of the catalysts outperformed the reference catalyst material, 20% Pt on C.

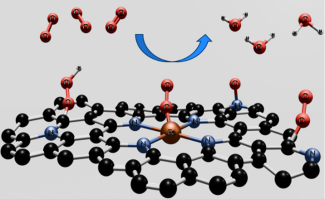

Addressing the instability issue of Fe-N4-C single atom catalysts for oxygen reduction reaction (Doo Young Kim, Chemistry)

Oxygen reduction reaction (ORR) is a key cathodic reaction that determine the overall efficiency of hydrogen fuel cells. Also ORR is a key half-reaction in electrochemical energy storage (e.g., metal-air batteries). Platinum (Pt) nanoparticles attached to high-surface-area carbon support (Pt/C) are a state-of-the-art cathodic electrode for ORR. However, Pt/C is not suitable for commercial applications because of the expensiveness and scarcity of Pt. Therefore, it is pivotal to develop alternative catalysts that require no or sufficiently less amount of platinum. Fe-N/C single atom catalysts (SACs), where earth-abundant iron (Fe) is atomically dispersed in porous, conductive graphitized carbon network, have shown excellent ORR activity, comparable to or exceeding commercial Pt/C. The coordination of Fe metal center with 4 nitrogen atoms (Fe-N4) enables Fe to have an optimal binding strength for adsorption and desorption of O2 molecules for ORR. Despite its great potential, a gradual decay in the long-term activity of Fe-N/C is a critical hurdle against the large-scale implementation of this catalyst in commercial fuel cells. It was reported that this instability is linked to the demetallation of Fe centers during ORR. The consensus is that Fe demetallation originates from insufficient bond strength between Fe and N ligands. To balance between ORR activity and stability, foundational knowledge of the structure-function-activity relationship of Fe-N/C as well as molecular-level modification of ligands are crucial. This project will (1) investigate ORR mechanistic pathway of Fe-N/C, (2) determine its deactivation mechanism, (3) determine its chemical nature and local microenvironment using various chemical probe and spectroscopic techniques, and (4) perform the molecular-level modification of ligands.

Multifilament spinning of PEDOT:PSS conductive fibers toward electronic textile applications (E. Ashley Morris, Center for Applied Energy Research)

Abstract not available.

Evaluating and eliminating electrode-induced degradation in organic electrochemical transistors (Alexandra Paterson, Chemical & Materials Engineering)

Organic electrochemical transistors (OECTs) simultaneously couple ionic and electronic charge transport. While OECT research has made significant advances in recent years, poor stability is the bottleneck impacting all technologies in the enormous OECT application space: From biosensors, medical devices for drug delivery, and adaptive healthcare technologies, to artificial synapses for coupling neurons and controlling prosthetic devices, neuromorphic hardware for advanced computing, and chemical sensing for precision agriculture. A key source of instability is the interface between the metallic electrode and conjugated polymer. This project combines Paterson’s (College of Engineering) OECT device fabrication and characterization with Graham’s (College of Arts and Sciences) electrochemical and photoemission spectroscopies to investigate chemical degradation reactions as a function of the electrode/organic interface in OECTs. The project uses both bare metal electrodes and metal electrodes with self-assembled monolayers (SAMs) to determine the impact of the metal/organic interaction on degradation reactions, while also testing the ability of the SAM to improve OECT stability. Overall, this project aims to enhance OECT stability, while uncovering the fundamental mechanisms thereof.

Nanoporous Materials for Selective Separation and Purification of Phenolic Oligomers from Lignin-First Biomass Processing (Stephen Rankin, Chemical & Materials Engineering)

Abstract not available.

Equipment Grants

Acquisition of Bruker S6 Jaguar Wavelength Dispersive X-Ray Fluorescence System for the Characterization of Advanced Materials and for Energy Applications (Nicolas Briot, Chemical & Materials Engineering)

Abstract not available.

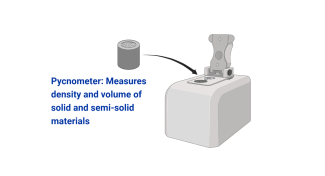

Acquisition of a pycnometer (Malgorzata Chwatko, Chemical & Materials Engineering)

Gas pycnometer was successfully purchased to provide enhanced capabilities to determine density and porosity of varying materials. The pycnometer has numerous cell sizes to accommodate varying specimen sizes. Samples such as polymers, ceramics, metals are expected to work well as long as enough sample is available. The instrument is available in ASTeCC, please reach out to Gosia Chwatko, m.chwatko@uky.edu for access.

X-ray powder diffraction (XRPD) analyzer upgrade (Cortland Eble, KY Geological Survey)

Abstract not available.

Acquisition of a Surface Profiler to be made available through the Center for Nanoscale Science and Engineering (Jeffrey Hastings, Electrical and Computer Engineering)

The new Bruker Dektak XT surface profiler is now available for use in the Center for Nanoscale Science and Engineering. The profiler quickly measures step heights and surface roughness up to 1 mm high over distances up to 50 mm. The built-in microscope allows alignment to specific features or areas of interest. In addition, the profiler features the 2D stress measurement option for determining thin-film stress and the low force measurement option for accurately characterizing soft samples without damage. The instrument is located in room A368 of the ASTeCC building (central campus, connected to Grehan, McVey, and Raymond). Requests for training and reservations for use may be made through Facility Online Manager (https://uky.fomnetworks.com/fom/) using your linkblue credentials. Please contact Todd Hastings (todd.hastings@uky.edu) with any questions.

New and Enhanced Research Infrastructure (Alexandre Martin, Mechanical Engineering)

Abstract not available.

Proposal for Diffuse Reflectance FT-IR Materials Analysis System (Robert Pace, Center for Applied Energy Research)

Abstract not Available.

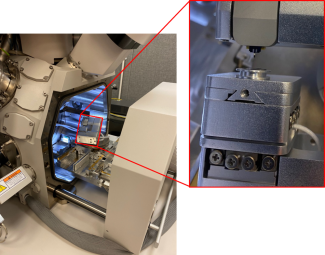

New and Enhanced Research Infrastructure: Building SEM In Situ Nanoindentation Capabilities (Paul Rottmann, Chemical & Materials Engineering)

The development of advanced materials is crucial for various real-life applications, from aerospace and automotive industries to biomedical implants and electronic devices. Understanding the mechanical properties of these materials at the micro- and nanoscale is essential for optimizing their performance and reliability in different environmental conditions. Our project aims to advance materials science by providing unprecedented insights into the mechanical behavior of Multi-Principal Element Alloy (MPEA) thin films under different treatment conditions, ultimately bridging the gap between nanoscale material behavior and macroscale performance. To achieve this goal, we are utilizing the FemtoTools In-situ SEM/FIB Nanoindenter (FT-NMT04), compatible with the Helios 660 SEM at the University of Kentucky's Electron Microscopy Center. This state-of-the-art system allows for real-time observation of material deformation processes during mechanical testing, providing a comprehensive understanding of the process-structure-property relationships in MPEAs.

The FT-NMT04 nanoindenter enables the quantification of critical mechanical properties such as hardness, elastic modulus, and strain rate sensitivity. With its impressive force range up to 200 mN and low noise floor of 500 nN, the system offers exceptional versatility and precision for our research. The nanoindenter is optimized for testing metals, ceramics, thin films, and micro-scale structures like metamaterials and MEMS. Its modular design with interchangeable tips (Berkovich, flat punch, and dog-bone tensile grip) and ability to apply both monotonic and cyclic loading allow for comprehensive material characterization. Typical applications of this advanced setup include quantifying plastic deformation mechanisms through micro-pillar compression testing, tension testing of dog-bone shaped specimens and thin films, and fracture testing of micro-cantilevers using continuous stiffness measurement (CSM) for J-integral quantification of fracture toughness and crack growth events.

Two 200 mN diamond tip Berkovich force sensing probes for this system were purchased using funds awarded by the m-RPA. The FemtoTools FT-NMT04 system is available for collaborative use. Interested m-RPA members should email Paul Rottmann (paul.rottmann@uky.edu).

Vouchers for User Center Access

Study of Atmospheric Particulate Matter (PM) by Scanning Electron Microscopy with Energy Dispersive X-ray Spectroscopy (SEM-EDS) (Marcelo Guzman, Chemistry)

Particulate matter (PM) with a diameter of ≤ 2.5 µm (PM2.5) from a pollution monitoring station is under investigation to characterize its structure and composition. Atmospheric PM is a significant global environmental concern due to its adverse effects on visibility and public health. Atmospheric PM exacerbates cardiovascular incidents and asthma episodes, posing a severe risk to vulnerable populations. This proposal outlines an international collaboration of Dr. Guzman aimed at collecting PM2.5 samples and identifying their mineral components using Scanning Electron Microscopy with Energy Dispersive X-ray Spectroscopy (SEM-EDS). The project not only advances the scientific understanding of PM2.5 but also provides unique training to a Ph.D. graduate student in advanced analytical techniques. This training spans the interdisciplinary fields of materials science and environmental science, equipping the student with a robust skill set. Additionally, the project aims to gather preliminary data essential for a National Science Foundation (NSF) proposal. This data will support future research endeavors of researchers at the University of Kentucky and contribute to the broader scientific community’s efforts to mitigate the impacts of atmospheric particulate matter. Through this collaborative effort, the project seeks to enhance our understanding of PM2.5 and develop strategies to address its detrimental effects on both the environment and human health.

Light Microscopy Core (LMC) Access Voucher (Aron Huckaba, Chemistry)

Abstract not available.

Electron Microscopy Core (LMC) Access Voucher (Aron Huckaba, Chemistry)

Abstract not available.

Enabling High-Resolution MicroCT of Porous Carbon Fiber Materials for Aerospace Applications (Paul Rottmann, Chemical & Materials Engineering)

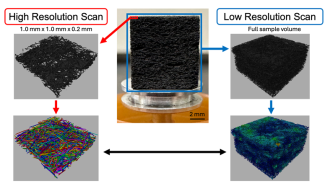

The inherent microstructural heterogeneity of porous, fibrous materials makes modeling and predicting the observed mechanical behavior of these materials difficult due to complex interactions across length scales. Experimental characterization at all length scales of interest is required to improve the accuracy and fidelity of current computational methods. Direct observation of these various length scales can be problematic using conventional mechanical testing techniques. Therefore, this project aims to utilize the characterization techniques available in the Electron Microscopy Center to full observe all the relevant length scales of the material during compression testing and mechanistically tie them to the observed mechanical behavior.

In order to accomplish this goal, the ThermoFisher Scientific HeliScan Mk2 has been utilized in combination with a Deben in situ micromechanical testing stage. Using this equipment, interrupted micromechanical compression tests have been completed on a porous, fibrous material to observe the local and global deformation behavior in 3D. Previous work in our group had been completed around observing this deformation behavior in 2D at a lower resolution. Given the expected and observed heterogeneity in the deformation initiation and evolution using 2D characterization, it was decided that 3D observation would allow for a significant increase in obtainable information and understanding of these materials.

During mechanical testing, the Deben in situ micromechanical testing stage was utilized to compression cubic specimens to prescribed displacements and full 360° microCT scans were acquired in the compressed state. Through this iterative procedure changes in local fiber density across various displacement levels could be observed and quantified. These results are then able to be tied to the strain behavior observed in 2D characterization to more fully understand how local density variations play a role in deformation initiation and evolution for porous, fibrous materials. Additionally, through the high resolution available utilizing microCT, individual fibers could be visualized and their properties could be quantified. Many current computational models utilize fiber level properties to predict the mechanical behavior in porous, fibrous materials. Therefore, experimental quantification of these properties allows for direct comparison between our results and the current computational models.

Conferences and Meetings

Expanding the Electron Microscopy Center’s staff imaging and characterization skillset to better support research in Materials Science at the University of Kentucky (Nicolas Briot, Chemical & Materials Engineering)

Abstract not available.

Application for m-RPA Travel Funding for Attendance of Society for American Archaeology 2024 Conference (Michael Detisch, Chemical & Materials Engineering)

The mRPA funding was used to support travel to the 2024 Society for American Archaeology Conference in New Orleans. This facilitated my attendance of a workshop presented by University of Missouri’s Missouri University Research Reactor group focused on Archaeometry, the discipline of applying quantitative analytical tools to archaeological questions such as ceramics sourcing.

While there I also co-presented a poster titled “Recent Geochemical Analyses of Ceramics from the Upper Basin Region of the Baaj Nwaavjo I'tah Kukveni Grand Canyon National Monument” which studied ceramic materials recovered from the area around Grand Canyon National Park. This research was generated as part of an EduceLab REU project and focused on the study of potsherds using optical microscopy and scanning XRF. By using scanning XRF systems at EduceLab (shown in the image top right) the paste or clay matrix of the potsherd could be distinguished from the temper added during pottery production. Studying the temper type and distribution within a pottery sherd as well as the composition of the clay itself can give information on pottery production techniques as well as materials sourcing. This in turn gives a unique glimpse into settlement areas, trade dynamics, and the way of life of people in the region during prehistoric times.

Student Fellows Program

CURE Fellowship - Office of Undergraduate Research (Chad Risko, Chemistry)

Conjugated polymers are an interesting class of materials that have garnered attention due to their unique and easily tunable electrical and optical properties, which lend well to their use in organic electrochemical transistors (OECTs), electrochromics, solar cells, lighting, displays, and energy conversation and storage applications. Achieving many of these unique properties requires “doping” the conjugated polymers – using chemical or electrochemical means to introduce hole or electron charge carriers to the material. As the precise number of charge carriers present on the polymer is highly correlated to its electronic, optical, and even morphological properties, quantifying how the state of the polymer changes throughout the doping process is critical to understanding what factors encourage the desired properties for a given application and maximize stability.

One of the most widely used techniques to characterize conjugated polymers is spectroelectrochemistry – the use of spectroscopic techniques (most commonly UV-VIS-NIR spectroscopy) to monitor changes in the polymer during electrochemical doping. However, traditional UV-VIS-NIR spectroscopy uses an absorbance-mode setup, which requires a substrate for the polymer which is both electrically conductive enough to act as an electrode and optically transparent to the wavelengths of interest. This requirement precludes the use of spectroelectrochemistry with many electrode materials, especially highly stable or biodegradable metals like gold or iron.

In this work, we developed an experimental setup for in-situ UV-VIS-NIR spectroelectrochemistry using reflection-absorbance spectroscopy. The approach quantifies the amount of light that is absorbed as light passes through the polymer sample, is reflected off the metal substrate, and continues back through the polymer and to the detector. The setup allows for the study of materials under different atmospheres (such as air or N2) and can be cheaply made by 3-D printing. The raw spectral data obtained in reflection-absorbance measurements is distorted relative to traditional absorbance methods by thin-film interference effects. However, we are developing a method to extract the true absorbance of only the polymer layer from the complex reflection-absorbance data. This approach is accomplished through a hybrid technique that combines dispersion analysis and variational dielectric fitting, which are both well-established in wave optics and used in other techniques like ellipsometry. Overall, our work establishes a technique for extension of spectroelectrochemical characterization of conjugated polymer materials in conditions previously experimentally inaccessible.